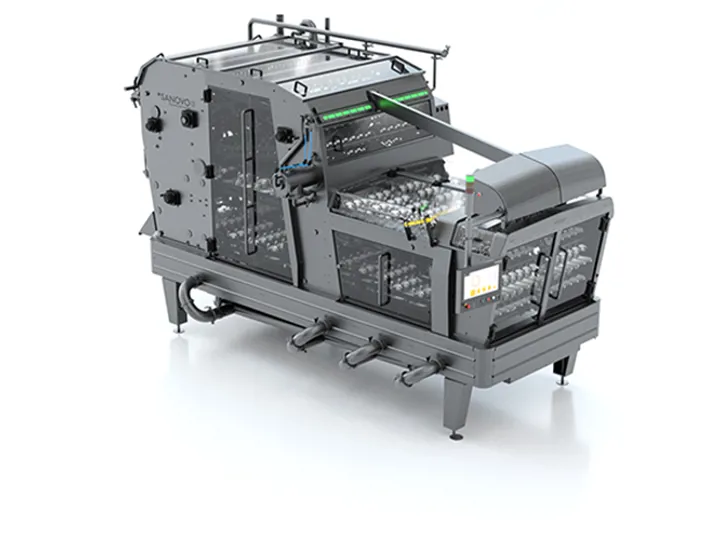

BreakerPro 12

- Up to 151,200 eggs/hour

- Up to 420 cases/hour

The OptiLoader Plus 12 is a reliable egg loading machine designed for off-line egg breaking operations. With its intelligent rotary design, it lifts eggs gently from trays and transfers them to the roller conveyor connected to the egg-breaking machine. Compatible with the OptiBreaker Compact 12, OptiBreaker Plus 12, and BreakerPro 12, this loader ensures precise and efficient handling for high-quality egg-breaking processes.

Capable of handling up to 151,200 eggs/hour (420 cases/hour), the OptiLoader Plus 12 accommodates various tray types, including pulp and plastic, providing maximum flexibility for different production needs. Empty trays are neatly stacked, and trays with stuck eggs are conveyed separately, ensuring uninterrupted operation.

Durability and easy maintenance are at the heart of its design, featuring independent drives synchronized with the egg breaker, optional CIP cleaning, and a Two-Step Blow-Back System for enhanced hygiene and performance.

The OptiLoader Plus 12 combines precision, flexibility, and efficiency to meet the demands of modern egg-breaking lines.

Browse through the resources available for this equipment. If you are in need of additional information you are welcome to submit a request through the "Contact us" button on this product.