OptiBreaker Plus 6

- Up to 72,000 eggs/hour

- Up to 200 cases/hour

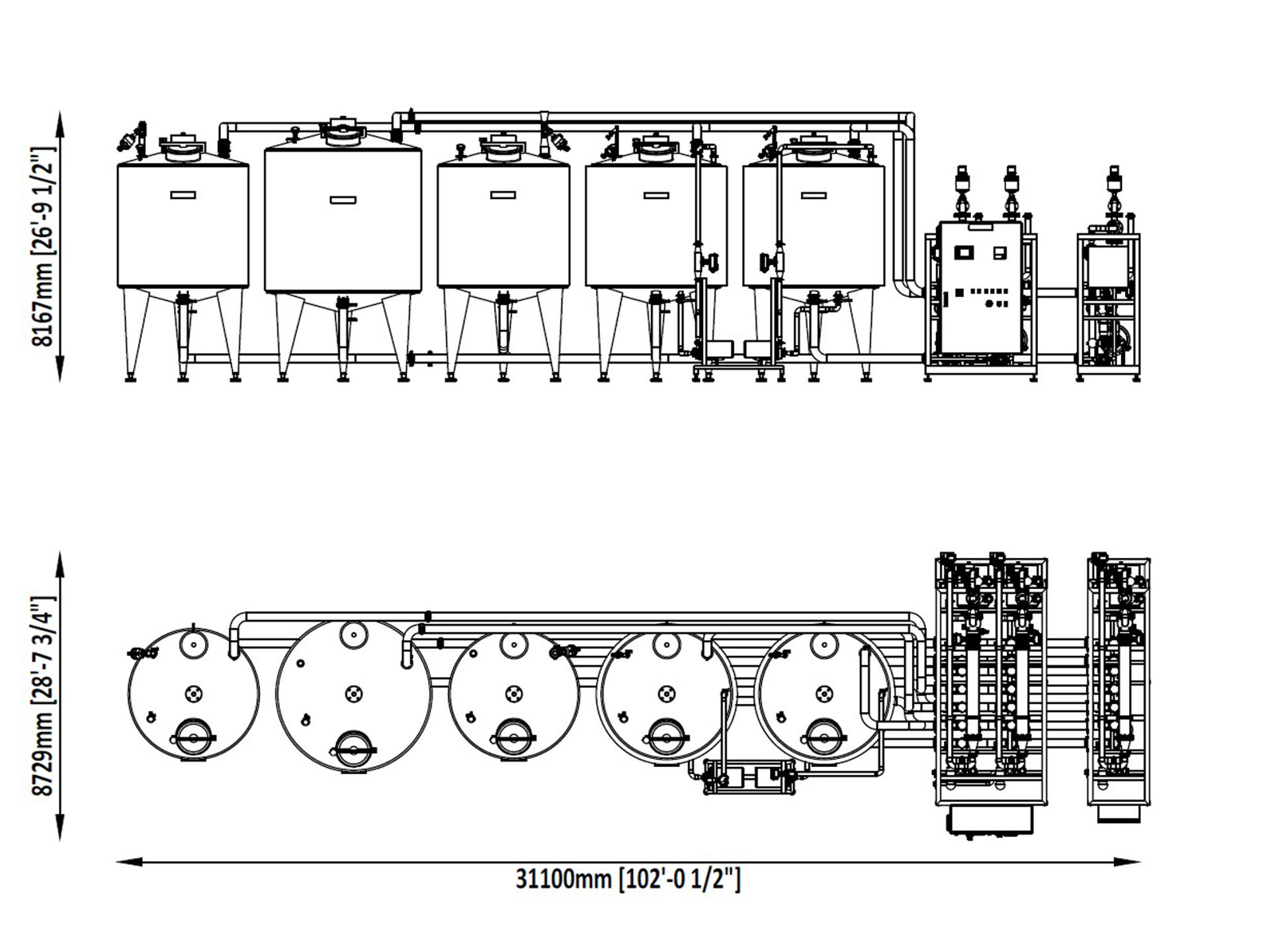

The SANOMAXI CIP is a complete cleaning plant suitable for the automatic cleaning of pipes, tanks, and other utilities within food processing, where a maximum flow rate of 30.000 l/h is required using a double chemical solution based on Caustic and Acid. The system is skid-mounted providing maximum layout flexibility.

Based on best-practice hygienic design principles, the system is set to clean with a minimum speed of 1,5m/s. That ensures a turbulent flow and good mechanical impact of the CIP in the pipes. SANOXMAXI is suitable for cleaning pipes up to three inches in diameter and therefore fits the most common pipes used in liquid food processing. Other than SANOMIDI and SANOMINI, SANOMAXI can clean 2 lines at a time to additionally reduce the time spent for cleaning. With SANOVO CIP systems you have full control over your cleaning operations.

Browse through the resources available for this equipment. If you are in need of additional information you are welcome to submit a request through the "Contact us" button on this product.