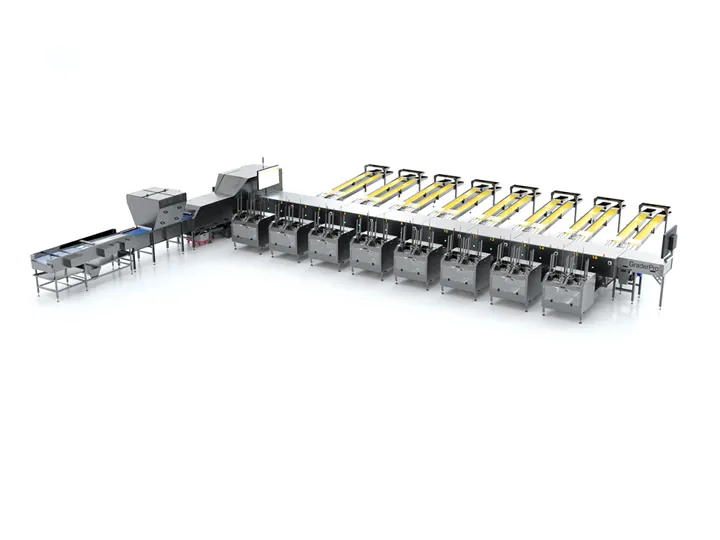

GraderPro 220

- 79,200 eggs/hour

- 220 cases/hour

The SANOVO Case Packer Twin is engineered for operations that manage frequent product changes, multiple consumer package types, and dynamic daily workflows. Built with larger robots and higher payload capacity, this system delivers exceptional flexibility while maintaining speeds of up to 160 cases/hour (57,600 eggs/hour) across two lanes.

Its advanced product gate system handles a wide range of pack sizes and carton formats, making the Case Packer Twin ideal for producers who switch between recipes and packing patterns often. Two operator screens—one on each side of the machine—ensure fast setup and quick adjustments during changeovers.

With options such as pass-through conveyors for manual packing, and full traceability integration (e.g., Ovotrack), the Case Packer Twin supports optimized resource use. One operator can efficiently operate multiple Case Packer Twin, significantly reducing labor requirements.

The Case Packer Twin is the ideal choice for modern egg grading and packing stations that require versatility, fast changeovers, and future-proof automation.

Browse through the resources available for this equipment. If you are in need of additional information you are welcome to submit a request through the "Contact us" button on this product.