In overall, the project was carried out and aligned across three plants, where SANOVO was involved in the following:

-

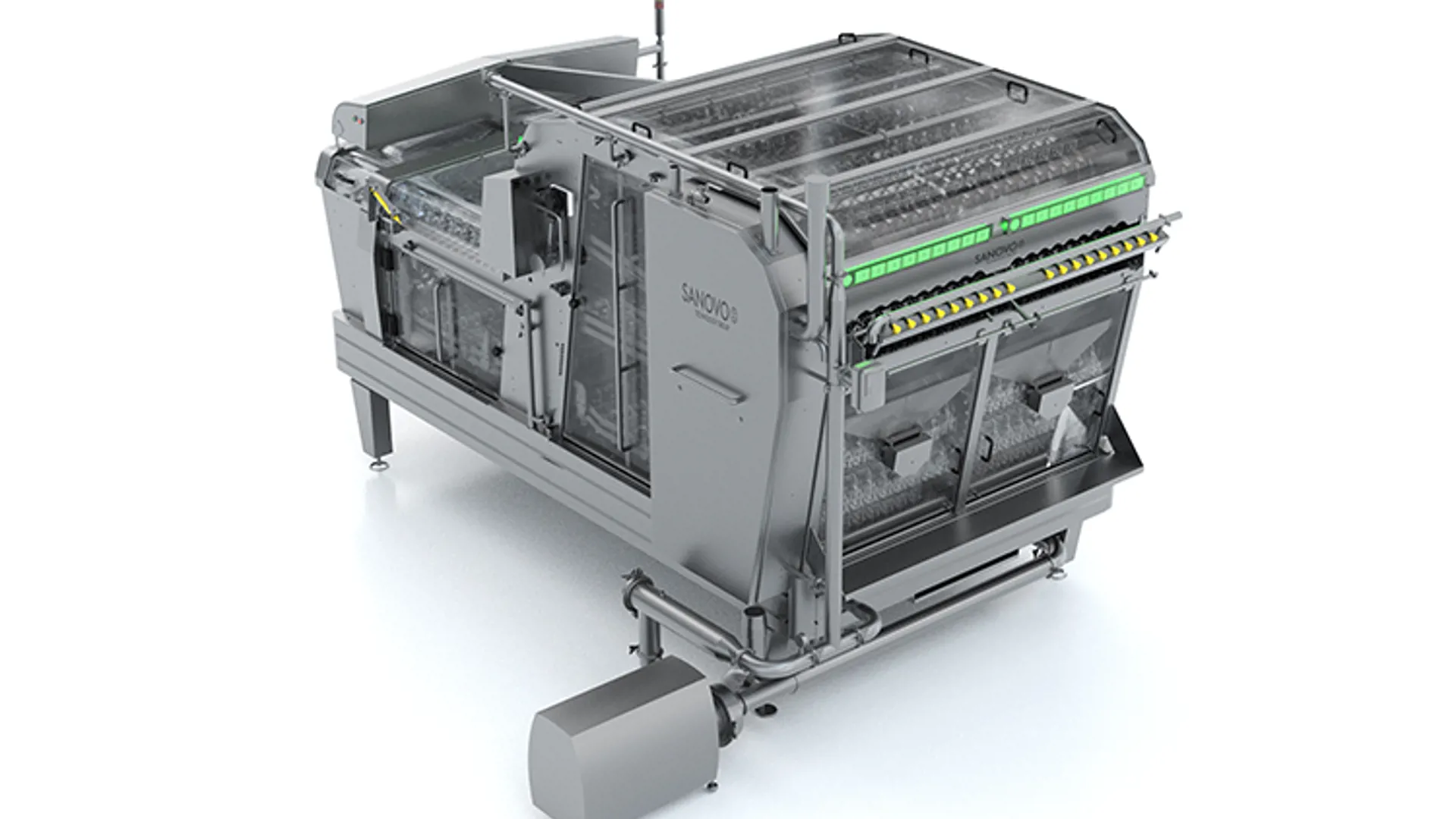

Monaldi plant: Integration of the automatic tray loading and utility washing system on an existing OptiBreaker 18 processing line. The plant is now Industry 4.0 compliant

-

COPRA plant: Integration of the automatic tray loading and utility washing system on an existing OptiBreaker 18 processing line. The plant is now Industry 4.0 compliant

-

MarcoPolo plant: Replacement of the existing breaker with the installation of a new Optibreaker 18 processing line with automatic tray loading and utility washing system.

Gruppo Eurovo: Innovation, Sustainability, and Family

At Eurovo, innovation, sustainability, and family are at the heart of everything they do. They are committed to continuous innovation through R&D, optimizing industrial processes, and selecting only the best raw materials. With a Benefit Company certification under their belt, they are dedicated to making a positive impact on both the society and the planet.

Family values are the compass that has guided Eurovo's journey from a small local business in the 1950s, started by Rainieri Lionello, all the way to an international powerhouse in the egg industry, still 100% owned by the Lionello family.

About three years ago, Eurovo saw an opportunity for technological advancement in their production plants and began looking into both replacing one of their existing breaking solutions and adding an automatic loading and tray, pallet, and interlayer washing solution. The equipment should also smoothly integrate with their existing machinery and streamline maintenance across the group. All in all, the desired outcome was to:

- improve efficiency in the loading area,

- reduce manual labor for more focus on quality control,

- optimize the overall egg processing setup.