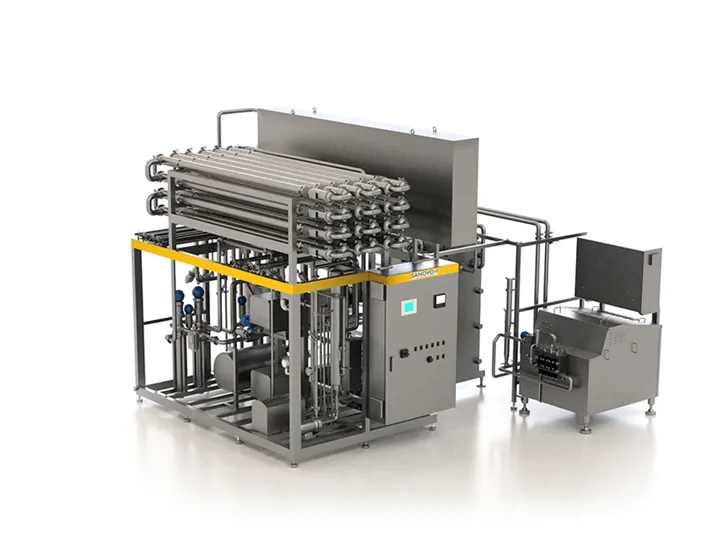

Pasteurizers or Sterilizers for liquid products

- 500 - 20,000 liters/hour

- Extended Shelf Life

The SANOMIDI CIP is a complete cleaning plant suitable for the automatic cleaning of pipes, tanks, and other utilities where a maximum flow rate of 25.000 l/h is required using a double chemical solution based on Caustic and Acid. The system is skid-mounted providing maximum layout flexibility.

Based on best-practice hygienic design principles, the system is set to clean with a minimum speed of 1,5m/s. That ensures a turbulent flow and good mechanical impact of the CIP in the pipes. SANOMIDI is suitable for cleaning of pipes up to three inches in diameter and therefore fits the most common pipes used in liquid food processing. With SANOVO CIP systems you have full control over your cleaning operations.