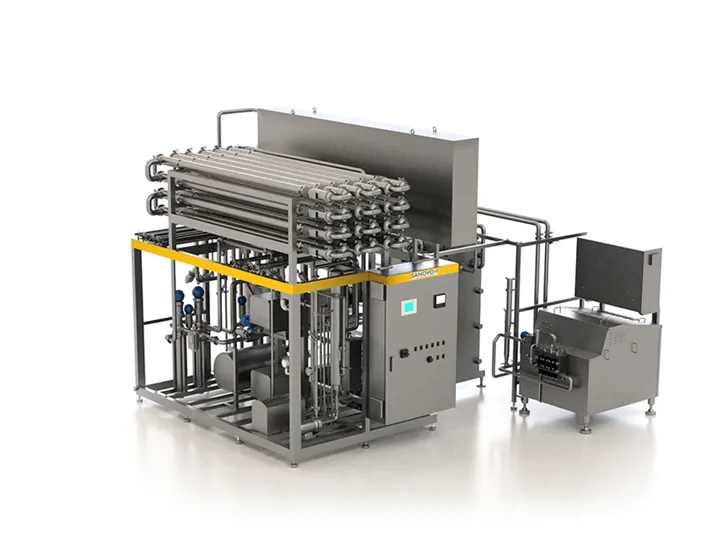

Pasteurizers or Sterilizers for liquid products

- 500 - 20,000 liters/hour

- Extended Shelf Life

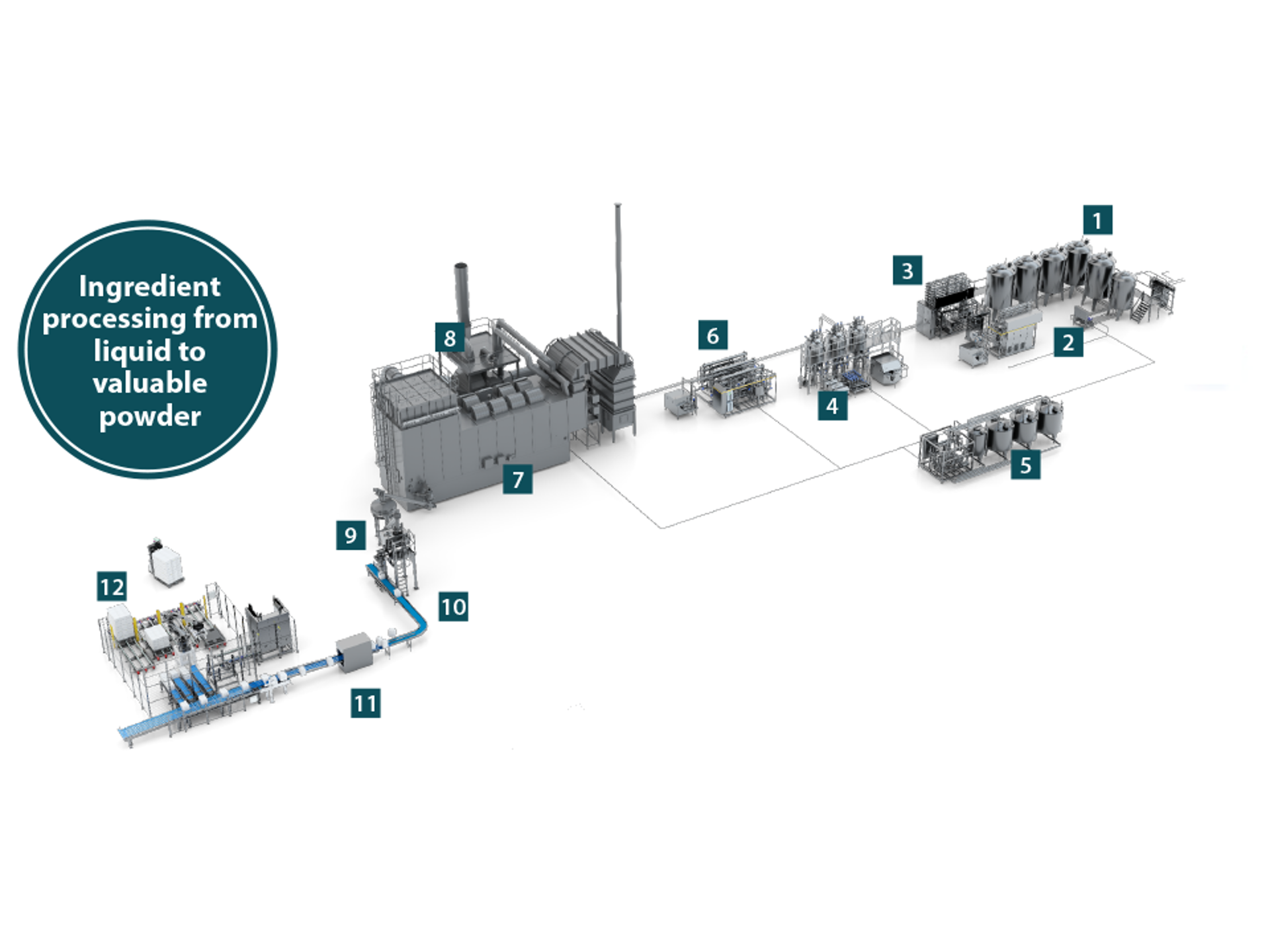

Our turnkey ingredient processing solution is built for safe, efficient, and high-quality production of valuable food, pet food, and feed ingredients, creating value by gently enhancing your finest ingredients into powder.

Designed as a complete factory configuration, this setup includes liquid feed preparation and heat treatment, advanced horizontal box spray drying, powder handling, and fully automated packaging solutions.

Ideal for operations transforming liquid raw materials into premium powder ingredients, this solution is configured to your exact processing needs, delivering efficiency, quality, and flexibility at every step.

Tap into the features below and explore each stage of the process in detail 👇

Browse through the resources available for this equipment. If you are in need of additional information you are welcome to submit a request through the "Contact us" button on this product.

We deliver versatile processing solutions for numerous different industries inclusive of animal and vegetable applications. We strive for a more sustainable future, that is why we take pride in optimizing your product’s end use possibilities and by doing so harnessing its full potential.

At SANOVO TECHNOLOGY PROCESS, we believe that our commitment to you doesn’t end with the delivery of our advanced processing equipment. Our Customer Care is designed to ensure you get the most out of your investment, providing comprehensive support and service every step of the way.